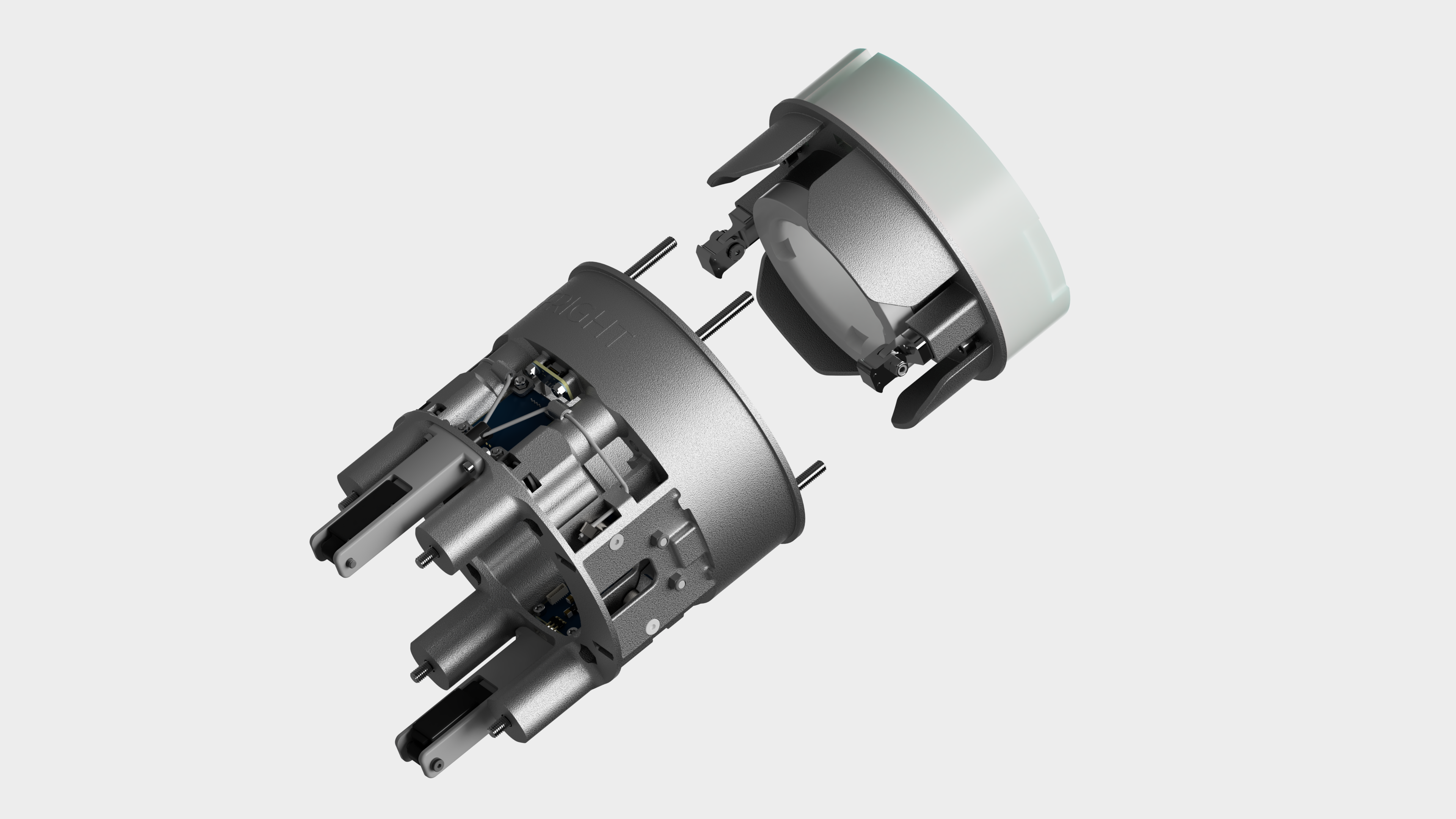

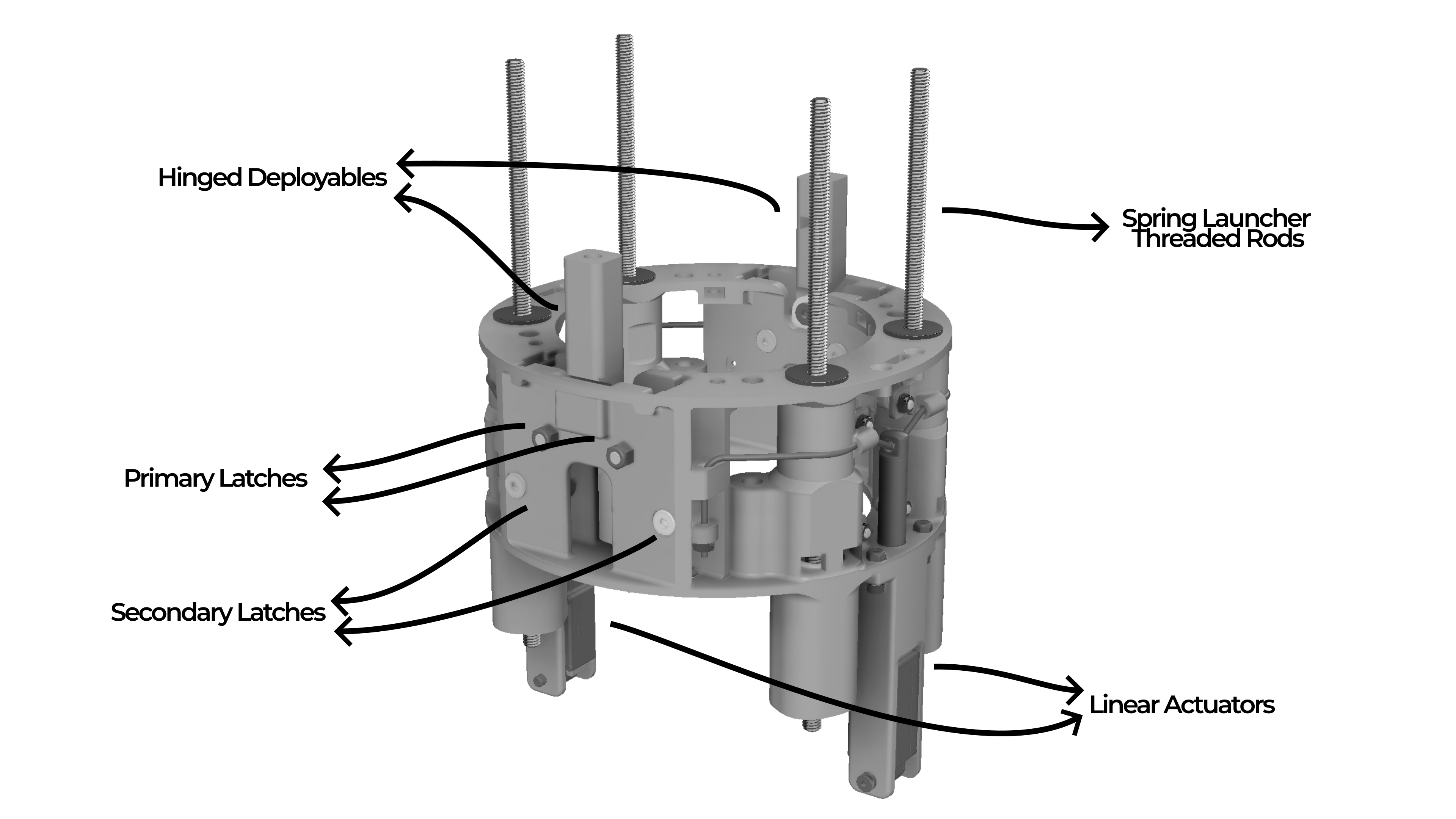

The 2025 Staged Release Mechanism (SRM) builds on 2023’s over-center latch architecture with several key advancements in redundancy, materials, sensing and electronics integration. It now employs two separate dual over-center latch arrangements on opposite sides to accomodate a booster motor, each driven by a high-torque cored metal-brush DC actuator with precision gearing. the latch systems are linekd by steel wire such that only one of the linear actuators are needed to release the deployables and thus separate the stages. Spring-loaded separators are now integrated directly within the SRM housing, delivering the kinetic energy needed for both parachute deployment and booster ignition under all recovery configurations. Both latch systems use ToF (Time-of-Flight) position sensors (±1 mm accuracy) to continuously verify latch position, feeding real-time data over dedicated, redundant I2C-bus channels to the central flight computer.

Constructed from selective laser melted (SLM) AlSi10Mg and SUS316L stainless steel, the 2025 SRM maintains the same overall weight as its 2023 predecessor, despite an increase in physical volume due to its more complex, multi-stage geometry. This optimization balances structural integrity with thermal and mechanical tolerances across all flight phases.

A set of custom-designed printed circuit boards (PCBs) forms the electrical backbone of the system, enabling seamless integration with breakaway USB-C connectors. These boards handle critical functions such as USB-C breakout, real-time sensor data aggregation, PWM control of the linear actuators, and regulated power distribution. The system is designed for top-down power and signal delivery with all electronics reside in the upper stage’s avionics bay, allowing the lower stage to remain completely passive. This architecture not only simplifies staging logic and reduces failure points, but also eliminates the need for redundant electronics in the booster stage. The HDRM continues to be fully resettable and consumable-free, with a manual reset process that takes less than two minutes, supporting fast and repeated ground testing of flight-critical separation events.

Development was driven by a multidisciplinary team of four NYU Abu Dhabi electrical engineering students. Instead of fabricating multiple hardware prototypes, the team employed co-simulation across MATLAB/Simulink, Simscale and Onshape to solve structural, thermal and kinematic challenges in the virtual domain. Only once performance objectives were met in simulation did they engage global vendors to machine and 3D-print flight-ready components.

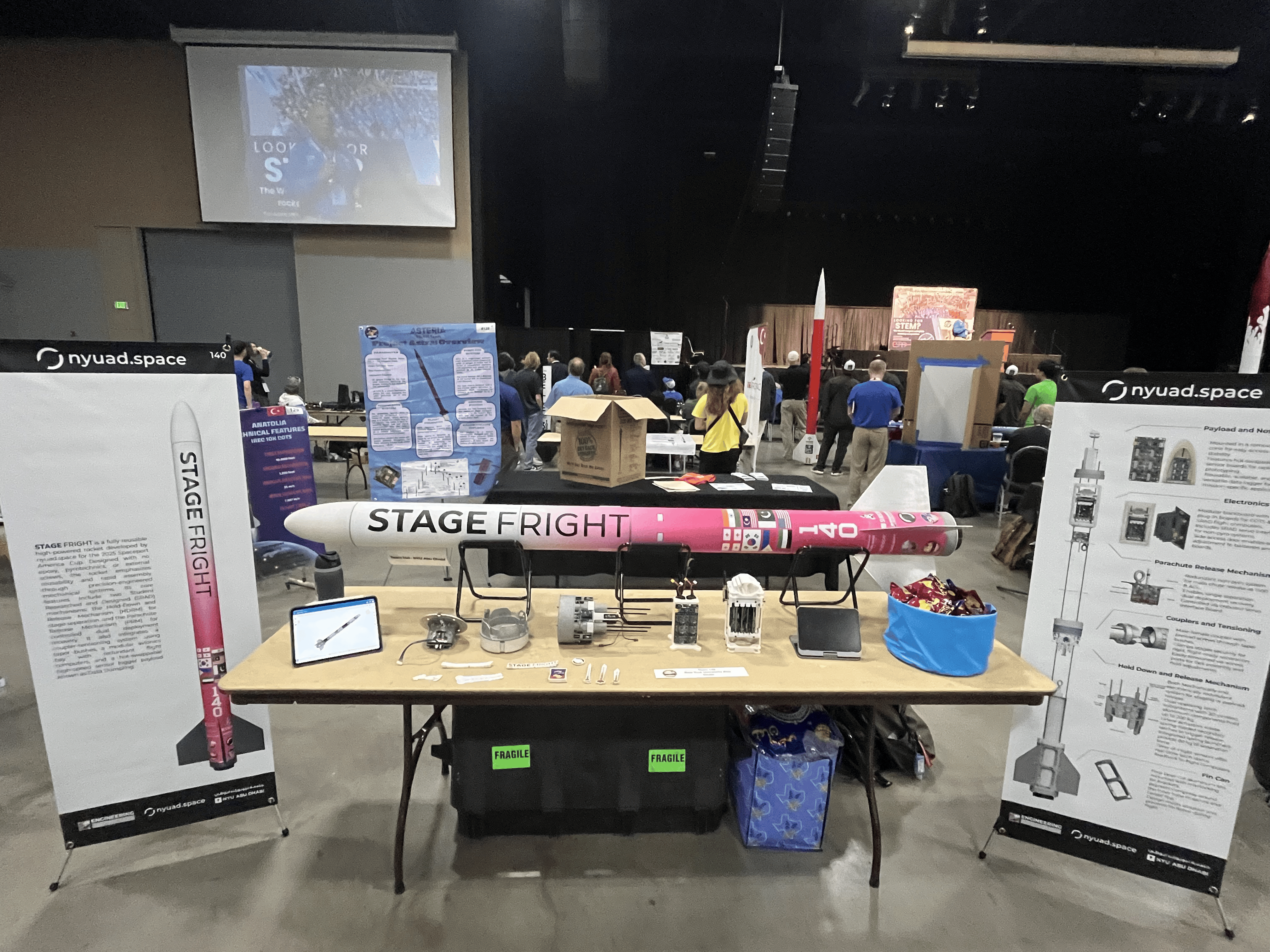

Flight qualification took place at the IREC 2025 launch in June, when the SRM successfully separated both stages of “Stage Fright” at 7770 ft, deploying the drogue parachute with zero anomalies. This iteration’s extreme reusability, multimode actuation and comprehensive health monitoring was designed with aerospace industry standards in mind.